Healthcare Rack Conveyors

The ingenious Intelligent Control System (ICS+) results in exceptionally low operating costs and a significantly reduced environmental impact.

ESE – Empty Space Elimination. This unique control system eliminates the empty space normally found between the baskets while they are being washed in the machine. In a normal dishwasher this empty space can account for up to 50% of the washing time.

CRT – Constant Rinse Time. The majority of rack conveyor machines have at least two speeds: one slow and one fast. When operating at the slow speed, the dishwasher can use up to double the amount of energy, water and chemicals. With CRT the time and the amount of energy and water needed for the final rinse does not depend on the contact time selected. Normally only around 1.0-1.4 litres of rinsing water are used per basket.

DTS – Double Transport System. When baskets are fed through a conventional rack conveyor machine, it is normal for the baskets to remain stationary 50% of the time. This results in high water consumption and unnecessary costs. By having an even speed through the rinsing zone, considerably less water is needed. ICS+ is equipped with DTS – a unique double feed system that feeds the baskets at an even speed to ensure optimum use of the rinsing water.

Wexiodisk WD-423 ICS+ – Three Stage Rack Conveyor

Product Features

- High performance three stage rack conveyor

- 135-305 baskets per hour standard

- 230 baskets per hour according to DIN10510

- 1 litre cold water consumption per cycle

- 377 litre wash tank volume including pre-wash tank

- Electronic control system

- Easy to use control panel to adjust contact time

- ICS+ ‘intelligent control system’ including ESE, CRT and DTS

- 3 x chemical wash zone

- Pre-wash zone with intermediate rinse

- Upper and lower angled wash and rinse arms

- Lightweight wash arms can be easily removed for cleaning

- 4 x 1.5kW wash pump with 12kW booster heater

- Self-emptying pumps in wash and rinse zones

- Easy to access large filters and strainer baskets for less frequent emptying

- High performance heat recovery system

- Condensate coil and heat exchanger to simultaneously reduce

- Heat emissions and heat incoming cold water

- Fully insulated doors and panels

- Stainless steel construction

- Removable front door for easy cleaning

- Tank can be emptied using easy access lever

- HACCP function

- Double final rinse zone

- Drain pipe positioned on the frame of machine for easy cleaning

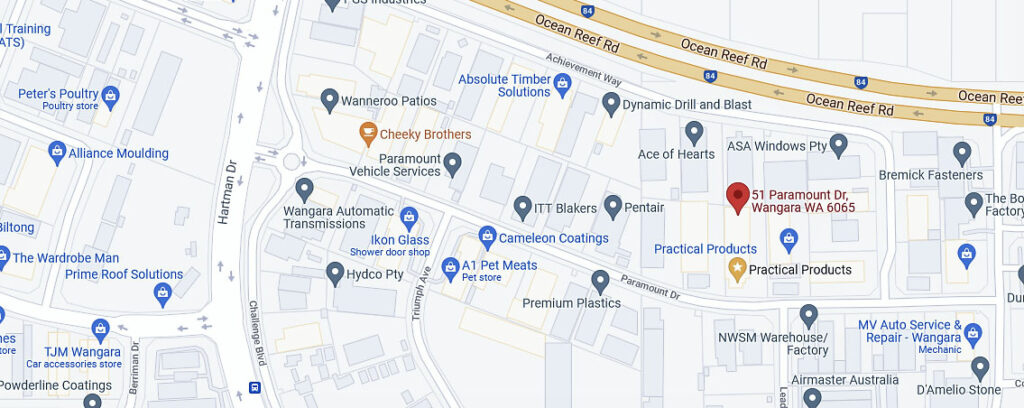

- Upgrades and options are available, please contact Practical Products

The ICS+ system is by far the best control system for rack conveyor machines. ICS+ is a cost-effective investment as it significantly reduces the consumption of chemicals, water and electricity.

Semi-lateral rinse pipes with optimized nozzles give a perfect spray pattern which divides the final rinsing water more accurate over the wash ware, giving lowest possible rinsing water consumption.

A comprehensive range with a capacity ranging from 70 to 285 baskets per hour.

The machines offer a good working environment and excellent wash results. The HACCP function in the electronic control system monitors the washing process. A text display panel makes the machines easy to use.

The large, well-balanced sliding doors make all the washing areas easily accessible. The doors can also be removed to allow the back of the machine to be cleaned. The new ICS+ has six different programmes for excellent wash results.

All the rack conveyor machines come with heat and sound insulation as standard, which improves the working environment in the dishwashing room.

The machines can be equipped with a pre-rinse zone, a drying zone, loading tables, conveyors, roller conveyors, conveyor bends and corner feed tables.

Wexiödisk’s rack conveyor machines are very easy to service and all the machines’ components are easily accessible.

As all servicing work is carried out from the front of the machines and all the water hoses are connected to the top, the machines can be positioned next to a wall, saving vital space.